With the continuous demand for varied paperweights in both small and large print centers, paper folding machines have become a fundamental piece of equipment. Whether you're handling short-run full-color work on heavier stocks or dealing with more traditional brochure jobs, choosing the right paper folding machine is paramount. Printers typically have two types of folders to choose from: conventional buckle plate folders and knife folding systems.

Understanding Paper Stocks

- Text Weight: Text weight sheets are thin and flexible, much like the paper you might use in a standard desktop printer. These sheets are often used for items like flyers and theses and can be coated or uncoated.

- Card Stock: Card stock, or cover stock, is thicker and more rigid. This type of stock is typically used for business cards, greeting cards, and perfect bound book covers, and it too can be coated or uncoated.

Buckle Plate Folders

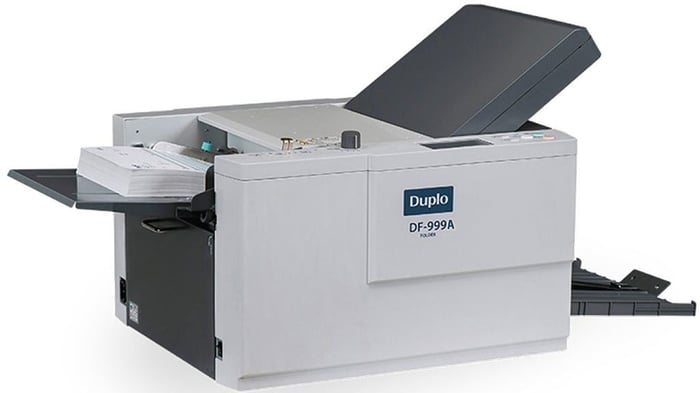

Buckle plate folders are commonly used in print shops. Their functioning involves a set of guides and plates that create folds in the paper. These buckle plate folders designed for digital printers are available in a range of automation levels and come with one of two types of feeding systems: Friction feed or Air / Suction feed.

Friction feed folders use spinning rollers to pull sheets of paper into the unit for folding. Although they can be useful for certain applications, friction feed folders often struggle with feeding coated papers and managing static caused by the digital printing process.

Air/suction feed folders address some of the limitations of friction feed systems. They are particularly effective for coated stock that has been digitally printed and therefore carries a lot of static. These systems can either be top fed or bottom fed.

Top-fed systems allow operators to load a job and leave the machine to do its work. Despite operating at slower speeds, the fact that these machines can run without constant supervision makes them a valuable asset for productivity.

Bottom fed systems, on the other hand, offer rapid operation and the ability to continuously load onto the pile for non-stop production.

Knife Folders

Knife folders are often the solution for folding card stock, which is generally more challenging than folding standard text weight stock.

When folding card stock, common problems include curling, cracking, and marking. However, machinery like the Morgana DigiFold Pro has been specifically designed to handle heavy substrates, mitigating these issues.

Knife folders use a "flying knife" technology to fold delicate digital stocks, cross-grained paper, and heavyweight stocks without causing any scratching or marking. The DynaCrease system used in these machines eliminates the cracking of toner and paper stock, providing high-quality output.

Despite their advantages, knife folders are not without their limitations. For instance, folding stocks under 80lbs can be a challenge due to the flexibility of lighter stock.

Making the Decision

When choosing a paper folding machine, it's crucial to consider factors such as minimum and maximum sheet size requirements, paperweights, volume, printing method, and long-term support.

Conclusion

Choosing the right paper folding machine depends largely on your specific needs and the range of stocks you plan to work with. By understanding the features and limitations of different types of machines, you can make an informed decision that optimizes your productivity and output quality.

FAQs

-

Q: What is the main difference between friction feed and air/suction feed folders?

A: Friction feed folders use spinning rollers to pull the paper into the machine for folding. They can struggle with coated papers and static. Air/suction feed folders use air to separate and feed the paper, making them better suited to coated stocks and digitally printed materials that retain a lot of static.

-

Q: What are the advantages of a knife folder?

A: Knife folders can handle delicate digital stocks, cross-grained paper, and heavyweight stocks without causing any scratching or marking. They also work with systems like DynaCrease to prevent cracking of toner and paper stock.

-

Q: What are the limitations of knife folders?

A: Knife folders can struggle with lighter stocks under 80lbs, as the flexibility of these sheets can lead to misfolding or jamming.

-

Q: When would I choose a top-fed system over a bottom-fed system?

A: A top-fed system can be left to run without constant supervision, making it ideal for situations where the operator needs to multitask. A bottom-fed system, on the other hand, offers faster operation and continuous loading for non-stop production.

-

Q: What factors should I consider when choosing a paper folding machine?

A: You should consider the minimum and maximum sheet sizes you need to handle, the types and weights of paper you'll be working with, the volume of work you need to process, your printing method, and the level of support you'll receive from your supplier.