Table of Contents

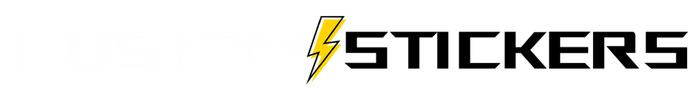

Die cut stickers are cut through the vinyl layer and the paper backing, creating a piece that’s trimmed to the exact shape of your design. Kiss cut stickers, on the other hand, have their top layer (the sticker material) cut in your desired shape, but the paper backing stays intact, leaving extra backing paper around the edges or behind the design. Both serve different purposes and offer unique advantages. Keep reading for more detail on kiss cut vs die cut stickers, including how each cutting process works, what shapes are possible, and which option might be best for your project.

Today we'll talk about the difference between two popular types of stickers - die-cut and kiss cut so you can decide which is better for your project.

What Are Kiss Cut Stickers?

Kiss cut stickers differ in one main way: the paper backing stays intact. In other words, the cutting blade only goes through the top layer of the sticker material (the vinyl layer), but it doesn’t cut all the way through the backing paper. As a result, you get a sticker (or multiple stickers) that peel away easily, but you also have extra backing paper around it. This extra border can contain additional information, artwork, or branding if you choose.

The Kiss Cutting Process

The kiss cutting process is often done by adjusting the cutting depth so the blade only kisses the sticker layer. That’s why it’s called kiss cut. The blade stops short of slicing through the entire thickness, leaving the paper backing intact in one piece. This method is ideal if you want sticker sheets with multiple designs or if you need delicate designs that might be hard to handle otherwise.

Benefits of Kiss Cut Stickers

Extra Backing Paper for Design

Kiss cut stickers often come on larger sheets or squares of paper. Since the paper backing stays intact, you have more space to work with. You can print your brand’s logo, contact info, website, or other details on the extra backing paper around the sticker edges.Easy Peeling

For intricate shapes with tiny edges, kiss cut stickers can be easier to peel because you’re not trying to pry them from a small, precisely cut edge. The extra backing paper gives you room to get a finger under the sticker’s corner.Multiple Stickers on One Sheet

You can fit multiple stickers on a single kiss cut sheet. This is convenient for promotional giveaways when you need a variety of designs, or if you want to include a series of small icons in a single sheet.Protective Border

If you have a design with lots of delicate details—like thin lines or small text—having that extra border can help prevent accidental tearing or curling. The top layer alone might be quite intricate, but the leftover paper makes it sturdier to handle.

Custom Sticker Sheets

$8.99

Custom Sheet Stickers | Waterproof Kiss Cut Stickers Custom Stickers are the full-color classics. Our Kiss Cut Sticker Sheets are a fast and easy way to promote your business, brand, or event. You can get multiple stickers on one sheet. Printed on… read more

What Are Die Cut Stickers?

Die cut stickers are produced by cutting through both the sticker material and its paper backing. In many ways, this is similar to a cookie cutter technique: a sharp metal die (or sometimes a digitally controlled blade) is used to cut stickers into a specific shape. When you hold a die cut sticker in your hand, there’s no extra border beyond the custom shape itself. It’s ready to apply right away, and the shape you see is the shape you get.

The Die Cutting Process

The die cutting process is straightforward. A cutting tool—like a metal die or a specialized cutting plotter—follows the outline of your artwork. It slices all the way through the vinyl layer and the backing paper. Because everything (top layer and backing) has been cut, the sticker pops out as an individual piece in your custom shape. These die cuts offer a very professional appearance. They look polished and well-finished, even before you peel the sticker off its backing.

Benefits of Die Cut Stickers

Professional Appearance

Because die cut stickers are trimmed to their exact shape, they appear very clean, with no excess material around the design. This gives them a more refined look on store shelves, or when handed out as promotional giveaways.Eye-Catching Designs

The shape of a die cut sticker can help your artwork stand out. You’re not constrained to squares or rectangles. If you want an intricate shape or a contour cut around a detailed logo, die cutting is a great option.Easy Handling

Die cut stickers come as a single piece, so they’re easy to hand out at events, trade shows, or even as freebies tucked into product packaging. Just peel and apply to surfaces like laptops, water bottles, bikes, or wherever you want your brand to appear.Versatile Applications

From branding to personal statements, die cut stickers are used for a variety of different purposes. In my opinion, they’re especially popular for businesses that want to make a statement with unique shapes, logos, or creative designs.

Die Cut Stickers

$8.99

Description Custom Die Cut Stickers | Waterproof Die Cut Stickers Selecting a size for your custom stickers means you are selecting the dimension of the longest or widest part of your sticker. We'll scale the image to this size. If you… read more

The Main Difference Between Die Cut and Kiss Cut

So, what is the difference between die cut vs kiss cut stickers, boiled down to a single sentence? It’s that die cutting slices through the vinyl and paper backing, while kiss cutting only goes through the top sticker layer, leaving the backing paper intact.

- Die Cut Stickers: Cut through the vinyl layer and the backing. No extra material around your sticker.

- Kiss Cut Stickers: Cut through the vinyl layer only. The backing sheet remains whole, creating a frame of extra backing around the sticker.

This difference influences how the stickers look and how they’re handled. Die cut stickers offer a self-contained shape that’s ready to peel. Kiss cut stickers offer a bit more detail in the sense that they can include additional artwork or text on the extra paper backing. Both can be printed on vinyl material or even paper-based sticker material, depending on your preference and budget.

Which Sticker Option Is Best for You?

When choosing between die cut and kiss cut, it often depends on what you need in terms of design and convenience. Here are a few scenarios:

You Want a Clean, Professional Look

Go with a die cut sticker if you prefer that neat, polished shape. Because the entire piece is trimmed to the desired shape, it can look more striking on packaging or product giveaways.You Want Extra Style or Information

If you’d like to include text, instructions, or decorative borders around your sticker, then a kiss cut sticker gives you the freedom to do so. The paper backing is intact, so you can get creative with additional branding.You Need Multiple Stickers on One Sheet

Kiss cut sheets are a nice solution if you want to provide several sticker designs at once. You can easily produce a sheet with multiple shapes and sizes. People can choose the design they want to use without having to sort through single stickers.You Have Intricate Shapes

Both die cutting and kiss cutting can handle delicate designs, but kiss cuts are often easier to peel in those scenarios. Since the backing paper is larger, there’s less risk of damaging the edges when trying to remove the sticker.You’re Looking for Cost-Effective Options

Both are typically budget friendly and fairly cost effective compared to some other promotional products. However, the real cost differences depend on your print provider, the quantity you’re ordering, and the complexity of the shapes.

Common Uses and Examples

- Business Branding: Custom die cut stickers featuring a brand’s logo are popular freebies. People often stick them on their laptops or water bottles, effectively spreading brand awareness.

- Labeling and Packaging: Kiss cut stickers are frequently used for product labels, especially when businesses want the convenience of a sticker sheet that includes multiple designs or sizes.

- Promotional Giveaways: When you’re tabling at events or looking for a cost effective way to reach people, handing out custom die cut stickers can leave a memorable impression.

- Decorative Purposes: If you run an online shop selling cute or decorative designs, both kiss cuts and die cuts can be used to showcase intricate artwork.

- Creative Projects: Designing personal sticker sheets or custom shapes for art journals, scrapbooks, or planners can be fun with kiss cutting. You might want to try a variety of shapes on one sheet to see which you like best.

Design Tips for Creating Stand-Out Stickers

When planning your sticker layout, keep a few design pointers in mind:

Choose the Right Material

Vinyl material is durable and weatherproof. This works well if you plan to use stickers on surfaces like bikes or water bottles. Paper-based sticker material can be a great option if you need a more cost-effective or eco-friendly route.Mind Intricate Details

Both kiss cuts and die cuts can handle intricate shapes, but too much detail can make a sticker harder to see from a distance. If your artwork is very delicate, test a sample. See if it’s easy to peel and read.Use High-Contrast Colors

For the best results, choose colors that stand out against each other. Clear text is crucial. If you have small text, make sure it’s a color that pops.Consider Your Backing Sheet

With kiss cut stickers, the extra backing paper can be used for additional branding elements or creative touches. If you’re going the die cut route, you can still select shapes that look great both on and off their surfaces.Don’t Forget Shape and Size

Think about how your sticker will be displayed. Are you fitting it on a small product box? A large laptop cover? The shape and size should match the space where it’s most likely to go.

Quick Pros and Cons Overview

Here’s a brief rundown of the advantages and disadvantages of each type:

Die Cut Stickers

- Pros:

- Clean edges and a professional appearance

- Great for promotional giveaways and single-design logos

- Ready-to-peel pieces with no extra material around them

- Cons:

- Might be trickier to remove if the shape is very detailed

- No extra space for printing additional info on the backing

Kiss Cut Stickers

- Pros:

- Paper backing stays intact, offering extra style and info

- Easy peeling, even for delicate designs

- You can put multiple designs on a single sheet

- Cons:

- The sticker itself might be less obvious when handing out since it’s in a larger sheet

- The extra border could feel less streamlined if you prefer a minimal look

Kiss Cut vs Die Cut - Making an Informed Decision

Now that you understand the main difference between die cut and kiss cut, you can make an informed decision. Both sticker options have their strengths, and the best choice depends on your branding goals, how you plan to distribute them, and how intricate your design is. For large giveaways or retail packaging, you might prefer die cuts for that sleek look. If you want to offer multiple stickers on one sheet or include extra style or instructions on the backing, kiss cuts are ideal.

Remember: the difference doesn’t end at how it’s cut. You should also think about the vinyl and paper backing you’re using. Are you aiming for a vinyl layer that’s waterproof, or a paper-based solution that’s more eco-friendly? Knowing your intended application helps you select the right sticker option for your project.

Final Thoughts

Stickers have come a long way since the first self-adhesive labels were invented in 1935. Today, both die cutting and kiss cutting are accessible techniques that bring creativity and convenience to promotional products, packaging, labeling, and personal projects. The difference between die cut vs kiss cut stickers might feel subtle, but it can influence how your final product looks and how people interact with it.

In the end, it’s about finding the right fit for your style, budget, and needs. If you need help, check with an experienced sticker provider or designer. They can guide you through the process, recommend specific shapes, and suggest ways to make your design stand out. Sometimes, a quick conversation can save you time, money, and frustration—plus, it can help ensure that your stickers look just as you imagined.

Whether you decide on die cut stickers or kiss cut stickers, you’ll have a fun, budget-friendly way to spread your message or add a personal touch to your belongings. And if you’re like me, you’ll find it hard to resist peeling one off immediately and sticking it on your favorite notebook. It’s just too tempting.

Frequently Asked Questions

Q: Can I use both die cut and kiss cut for the same design?

A: Technically, yes. You can create custom die cut stickers for a simpler design or have the same artwork produced as a kiss cut sticker sheet if you want additional info around it. It’s more about your preference than anything else.

Q: Are die cut stickers or kiss cut stickers more durable?

A: Both can be printed on durable vinyl. The durability usually depends on the printing method, laminate finish, and the sticker material rather than the cutting method. If you plan to use stickers in tough environments—like on cars or bikes—opt for a weatherproof vinyl layer with a protective laminate.

Q: Do I have to choose a specific shape?

A: You have endless possibilities. Die cuts and kiss cuts can handle unique shapes or standard squares and circles. The main difference is whether you want extra backing paper around it.

Q: Are they both easy to apply?

A: Yes, both are generally easy to apply. But with kiss cut stickers, you often get easier peeling because of the larger backing sheet. Die cut stickers can sometimes have more fiddly edges if the design is intricate.

Q: Do I need a special design file for die cutting?

A: Many printers require a vector file or a high-resolution image with a clear cut line. Ask your printing provider what they need. Typically, they’ll outline your shape for precise cutting, whether you’re dealing with die cuts or kiss cuts.